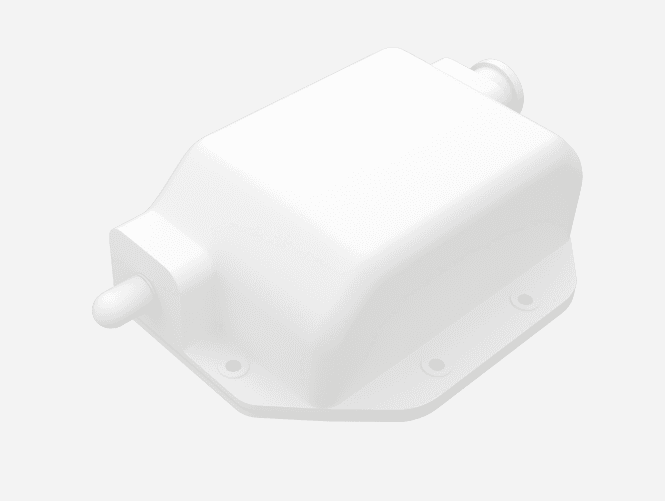

Iomico provides awards-winning industrial design and mechanical design of enclosures from plastic and metal for various electronic devices, including IP68-rated enclosures for:

Smart devices: Trackers, Watches, Collars, Sensors, Detectors and etc.

Modems, Hubs, Routers, Gateways

Cameras

Smart Fridges

Medical devices

Multi-port switches

Industrial switches

Video game consoles

Dosimeters

Glucometers

Tablets

Phones

Flash drives

Binoculars

Musical devices

And others

Devices can be based on ready-made (purchased) housings or custom-designed. Enclosures can be made of sheet metal, plastic, plastic combined with rubber or soft touch coatings, silicone products, milled from solid metal, and others.

Iomico is capable of designing enclosures of various complexities from:

Plastics, obtained by methods such as:

Injection molding, including two-component molding

Extrusion

Rotational molding

Blow molding

Hot and cold forming

Casting into silicone molds

Mechanical processing (turning and milling operations)

Aluminum and steel, obtained by methods including:

Die casting

Extrusion

Various mechanical processing (turning and milling operations on CNC machines, electrical discharge machining, grinding, etc.)

Sheet metal, obtained by:

Stamping

Bending

Cold and hot embossing

Various metal-cutting methods

3D printing, using various methods such as:

Extrusion (FDM)

Photopolymerization (SLA, SLA-DLP)

Laser sintering (3DP, EBM, SLS, DMLS, SHS)

And others

Our team of experts provides designs with movable mechanics. Designing movable assemblies and mechanisms using motors, reducers, pneumatics, hydraulics

Additionally, we perform various modeling and calculations:

Calculation of plastic mold filling. Results include filling speed, shrinkage, warpage, burns, weld lines, and short shots.

Calculation of housing squeak under load

Calculation of drop impact

Calculation of heat dissipation and movement

Other engineering calculations related to the behavior of parts and mechanisms under load